- Products

-

Paper and board

- Water treatment

- Wood and chip yard

- Pulp making

- Pitch control

- Defoamers

- Press fabrics

- Detergents

- Strength enhancers (Biopolymer)

- Additives for wet strength broke pulping

- Additives for fiber modification

- Additives for peroxide bleaching

- Magnesium hydroxide

- Enzymes

- Organic Deposit Control

- Inorganic Deposit Control

- Edge showers

- Adjustable shower pipes

- Scanjet tank cleaners

- iFibre

- Starch Performer starch cooker

- Screw presses

- Double wire presses

- Disc filters

- Bale handling systems

- Baler wires

- Wire section

- Defoamers

- Dewatering elements, ceramics and PE

- iTable and dewatering elements optimization

- Dewatering elements

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Fabric cleaning and conditioning

- Slime control

- Banform SSB wires

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- TableVision – Activity Vision

- TableVision – Jet Vision

- TableVision -Line Vision

- TableVision – FlocVision

- Fabric Guides

- Retention agents

- Press section

- Drying

- Air flotation dryers and air turn solutions

- Fabric cleaning agents

- Degreasers

- Yankee roll release agents

- Bandry woven dryer fabrics

- Bandry PPS hydrolysis resistant dryer fabrics

- Bandry fabrics for broke conveyor

- Electric Infra-Red dryers – DryMaster™

- Electrical IR wet edge dryers – EdgeMaster™

- Gas IR and air drying systems – UniDryer®

- Energy recovery systems

- Gas IR dryers – GemDryer®

- Air dryers – FoilMaster™

- Coating

- Reeler and finishing

- Monitoring

-

Chemical pulping

- Water treatment

- Wood and chip yard

- Fiber line

- Drying

- Pitch control

- Defoamers

- Adjustable shower pipes

- Dewatering elements, ceramics and PE

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- Fabric Guides

- Safetymaster

- Strength enhancers (Biopolymer)

- Dewatering elements optimization

- Microbiological control

- Cylinder protection agent

- Forming fabrics

- Baler wires

- Recovery

- Condition monitoring

- Mechanical forest industry

- Biomaterials

- Green transition sectors

- Electrification and energy solutions

- Biogas and biofuels

- Petrochemicals

- Mining industry

- Metal industry

-

Paper and board

-

Partners

- Acrowood

- AstenJohnson Advanced Fabrics

- Bellmer

- BERGER

- Bollfilter

- Broadwire

- Buckau-Wolf GmbH

- CERNEY

- Eaton

- ECOWORLD

- FMW Industries

- GIG Karasek

- HeatHamster

- Herco

- Horst Sprenger

- IBS Austria GmbH

- Ichikawa

- Innocode

- Ircon Solaronics

- James Ross

- JTR ROLLS

- JUD AG

- Kapotek

- KOHO

- LMF

- MAAG Group

- Meidinger AG

- Papertech

- PGA

- Pieralisi

- Pirobloc

- PMS

- Renk Group

- Scanjet Systems

- Schaumann Bioenergy

- sera Group

- Spooner Industries Limited

- Teufelberger

- Transphase

- UMV Coating Systems

- Vakuo

- Sustainability

- Company

- Contact us

Products

Edge showers and edge trimming

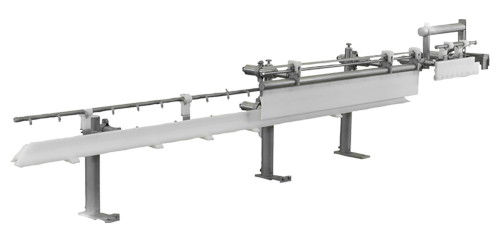

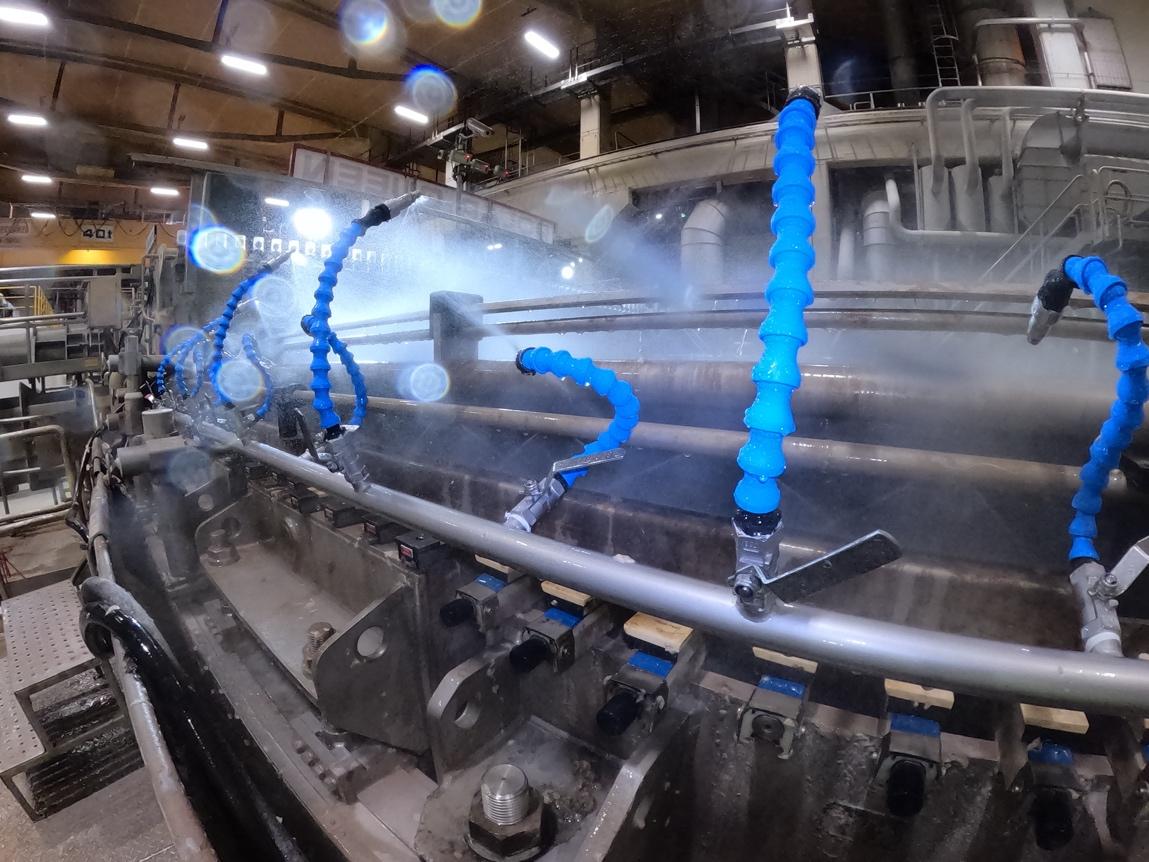

IBS Edge Control

IBS Edge Control improves the edge control of the pulp as soon as the paper wire exits the forming box. The adjustable base with a Teflon insert ensures perfect sealing, reducing fiber buildup and tears. The optimized washing system prevents fiber accumulation and keeps the unit clean during production. It is compatible with all coating box models and can be easily retrofitted.

Benefits:

- Fewer edge waves

- Improved CD basis weight, moisture, and TSO angle

- Optimized spray system ensures clean operation

- Fully adjustable during machine operation

- Quick thread change with release needles

- Suitable for retrofitting

IBS Wave Control

Smooth and High-Quality Paper Edges

The IBS Wave Control system completely eliminates edge waves, ensuring uniform paper quality and clean edges. The optimized use of showers enables a continuous and simple cleaning process. Thanks to quick-release pins, the system can be easily removed for wire changes without the need for additional tools.

Benefits:

- Completely eliminates edge waves

- Improves basis weight, moisture, and TSO angle profiles

- Easy to align and adjust

- Quick removal for wire changes

New-Type Edge Washer

The new-edge washer enhances the performance of your corrugating machine by reducing production downtimes and enabling higher speeds, especially with heavier grades of paper. Its advanced design improves edge control, reduces pulp waste, and allows for faster machine speeds.

New Edge Washer – Key Benefits:

- Better Edge Control – Clean and well-managed wire edges.

- Fewer Breaks – Edge-related breaks are significantly reduced.

- Cleaner Finish – Improved cleanliness of the edge area.

- Easy Adjustment – Fast and flexible adjustments during grade changes.

- Quick Wire Change – Rotating structure allows for wire change without tools.

- Precise Spray Control – The spray can be accurately directed.

According to user feedback, breaks have almost been eliminated, and the adjustable sprays and quick wire change have received particular praise. The edge washer improves cleaning efficiency and saves significant production time.

Contact us

Pasi Kostamo

Available

- FI