- Products

-

Paper and board

- Water treatment

- Wood and chip yard

- Pulp making

- Pitch control

- Defoamers

- Press fabrics

- Detergents

- Strength enhancers (Biopolymer)

- Additives for wet strength broke pulping

- Additives for fiber modification

- Additives for peroxide bleaching

- Magnesium hydroxide

- Enzymes

- Organic Deposit Control

- Inorganic Deposit Control

- Edge showers

- Adjustable shower pipes

- Scanjet tank cleaners

- iFibre

- Starch Performer starch cooker

- Screw presses

- Double wire presses

- Disc filters

- Bale handling systems

- Baler wires

- Wire section

- Defoamers

- Dewatering elements, ceramics and PE

- iTable and dewatering elements optimization

- Dewatering elements

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Fabric cleaning and conditioning

- Slime control

- Banform SSB wires

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- TableVision – Activity Vision

- TableVision – Jet Vision

- TableVision -Line Vision

- TableVision – FlocVision

- Fabric Guides

- Retention agents

- Press section

- Drying

- Air flotation dryers and air turn solutions

- Fabric cleaning agents

- Degreasers

- Yankee roll release agents

- Bandry woven dryer fabrics

- Bandry PPS hydrolysis resistant dryer fabrics

- Bandry fabrics for broke conveyor

- Electric Infra-Red dryers – DryMaster™

- Electrical IR wet edge dryers – EdgeMaster™

- Gas IR and air drying systems – UniDryer®

- Energy recovery systems

- Gas IR dryers – GemDryer®

- Air dryers – FoilMaster™

- Coating

- Reeler and finishing

- Monitoring

-

Chemical pulping

- Water treatment

- Wood and chip yard

- Fiber line

- Drying

- Pitch control

- Defoamers

- Adjustable shower pipes

- Dewatering elements, ceramics and PE

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- Fabric Guides

- Safetymaster

- Strength enhancers (Biopolymer)

- Dewatering elements optimization

- Microbiological control

- Cylinder protection agent

- Forming fabrics

- Baler wires

- Recovery

- Condition monitoring

- Mechanical forest industry

- Biomaterials

- Green transition sectors

- Electrification and energy solutions

- Biogas and biofuels

- Petrochemicals

- Mining industry

- Metal industry

-

Paper and board

-

Partners

- Acrowood

- AstenJohnson Advanced Fabrics

- Bellmer

- BERGER

- Bollfilter

- Broadwire

- Buckau-Wolf GmbH

- CERNEY

- Eaton

- ECOWORLD

- FMW Industries

- GIG Karasek

- HeatHamster

- Herco

- Horst Sprenger

- IBS Austria GmbH

- Ichikawa

- Innocode

- Ircon Solaronics

- James Ross

- JTR ROLLS

- JUD AG

- Kapotek

- KOHO

- LMF

- MAAG Group

- Meidinger AG

- Papertech

- PGA

- Pieralisi

- Pirobloc

- PMS

- Renk Group

- Scanjet Systems

- Schaumann Bioenergy

- sera Group

- Spooner Industries Limited

- Teufelberger

- Transphase

- UMV Coating Systems

- Vakuo

- Sustainability

- Company

- Contact us

Products

iStop

Non marking winder automation solution

iSTOP+TM represents the industry’s first non-marking solution for accurately measuring the machine direction (MD) sheet position at the winder. There is no need for ink, lasers, or any type of marking when using our iStop+TM camera image pattern matching solution (patent pending). The maintenance and safety issues associated with ink and laser type marking are eliminated from winder control, with the added benefit of increased system reliability.

- Eliminates the need for messy and ongoing maintenance requiring ink code marking, or any other marking solution.

- Prevents breaks by accurately addressing critical defects. (Stop-on-Defect/Slow-on-Defect)

- Stores customer roll map data for further processing.

- Versatile usage, e.g. winder, calender and off-line-coater.

- Enables manual or automatic stopping at any position.

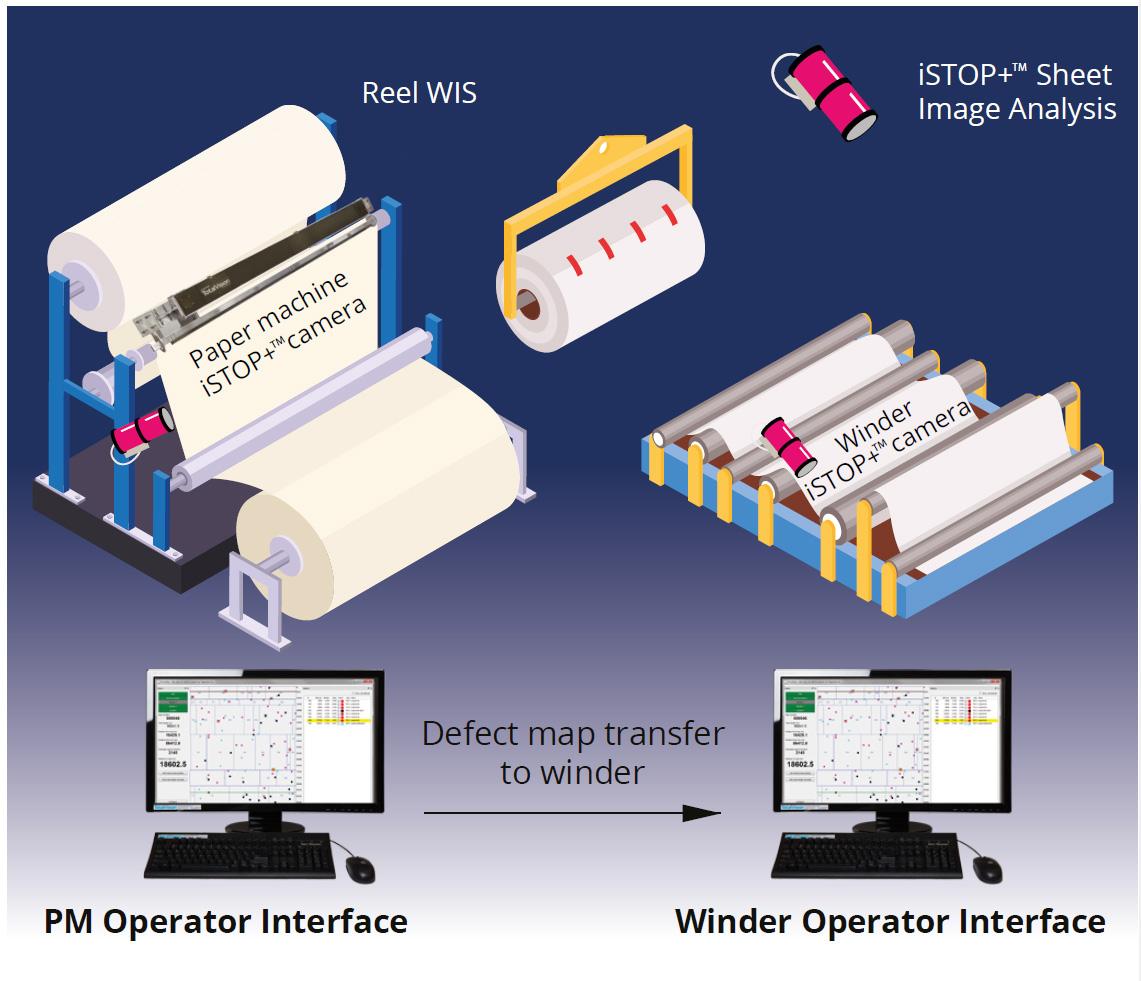

How it works

- iSTOP+™ camera on paper machine continuously inspects the sheet at the reel and stores unique image pattern machine direction (MD) information into the specific reel number.

- iSTOP+™ camera on winder continuously inspects the same sheet in the same area and finds the matching unique image pattern, resulting in the exact MD position being established.

- iSTOP+™ transfers continuously MD position data to winder software.

- The winder operator chooses defects to stop for, with critical ones preset for automatic stops. Depending on paper grades, the winder adjusts speed or stops with an accuracy of up to ±0.5 meters, optimizing its response based on the winder model and conditions.