- Products

-

Paper and board

- Water treatment

- Wood and chip yard

- Pulp making

- Pitch control

- Defoamers

- Press fabrics

- Detergents

- Strength enhancers (Biopolymer)

- Additives for wet strength broke pulping

- Additives for fiber modification

- Additives for peroxide bleaching

- Magnesium hydroxide

- Enzymes

- Organic Deposit Control

- Inorganic Deposit Control

- Edge showers

- Adjustable shower pipes

- Scanjet tank cleaners

- iFibre

- Starch Performer starch cooker

- Screw presses

- Double wire presses

- Disc filters

- Bale handling systems

- Baler wires

- Wire section

- Defoamers

- Dewatering elements, ceramics and PE

- iTable and dewatering elements optimization

- Dewatering elements

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Fabric cleaning and conditioning

- Slime control

- Banform SSB wires

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- TableVision – Activity Vision

- TableVision – Jet Vision

- TableVision -Line Vision

- TableVision – FlocVision

- Fabric Guides

- Retention agents

- Press section

- Drying

- Air flotation dryers and air turn solutions

- Fabric cleaning agents

- Degreasers

- Yankee roll release agents

- Bandry woven dryer fabrics

- Bandry PPS hydrolysis resistant dryer fabrics

- Bandry fabrics for broke conveyor

- Electric Infra-Red dryers – DryMaster™

- Electrical IR wet edge dryers – EdgeMaster™

- Gas IR and air drying systems – UniDryer®

- Energy recovery systems

- Gas IR dryers – GemDryer®

- Air dryers – FoilMaster™

- Coating

- Reeler and finishing

- Monitoring

-

Chemical pulping

- Water treatment

- Wood and chip yard

- Fiber line

- Drying

- Pitch control

- Defoamers

- Adjustable shower pipes

- Dewatering elements, ceramics and PE

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- Fabric Guides

- Safetymaster

- Strength enhancers (Biopolymer)

- Dewatering elements optimization

- Microbiological control

- Cylinder protection agent

- Forming fabrics

- Baler wires

- Recovery

- Condition monitoring

- Mechanical forest industry

- Biomaterials

- Green transition sectors

- Electrification and energy solutions

- Biogas and biofuels

- Petrochemicals

- Mining industry

- Metal industry

-

Paper and board

-

Partners

- Acrowood

- AstenJohnson Advanced Fabrics

- Bellmer

- BERGER

- Bollfilter

- Broadwire

- Buckau-Wolf GmbH

- CERNEY

- Eaton

- ECOWORLD

- FMW Industries

- GIG Karasek

- HeatHamster

- Herco

- Horst Sprenger

- IBS Austria GmbH

- Ichikawa

- Innocode

- Ircon Solaronics

- James Ross

- JTR ROLLS

- JUD AG

- Kapotek

- KOHO

- LMF

- MAAG Group

- Meidinger AG

- Papertech

- PGA

- Pieralisi

- Pirobloc

- PMS

- Renk Group

- Scanjet Systems

- Schaumann Bioenergy

- sera Group

- Spooner Industries Limited

- Teufelberger

- Transphase

- UMV Coating Systems

- Vakuo

- Sustainability

- Company

- Contact us

Products

Electric and gas duct heaters

Ircon solaronics provides industrial solutions for the electrification of various air dryers.

Electricity can be used as a source of energy for convection dryers to replace existing dryers with gas burners or steam coils.

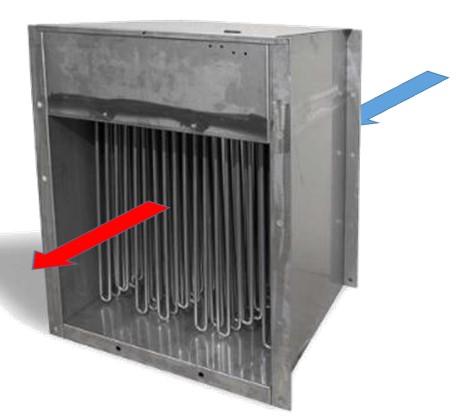

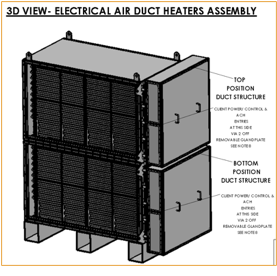

An electric duct heater consists of heating elements (tubes with resistance coils) placed in a casing which is connected to the ducts of the dryers.

The heater is equipped with a junction box in which the electrical connections of the heating elements are assembled.

The junction box is sealed to prevent heat transfer into the housing.

Electric resistance packages can be installed in place of or alongside existing gas heaters as a hybrid solution, allowing the choice of heat source according to the cost of energy.

We have implemented both solutions in Finland.

The power can be adjusted from 0 to 100% infinitely variable.

The third option is a steam radiator, where we can compensate for any reduced drying capacity with electrical inputs.

We also provide turnkey solutions including mechanical-, piping-, electrical-, automation installations, as well as software programming for different operating systems if required.

Replacing the gas burner with an electric duct heater usually leads to an improvement in the overall efficiency of the whole system => the energy used for evaporation (kWh/kgH2O) is reduced after electrification.

The reasons for this improvement are the following:

- The gas burner needs combustion air for the combustion reaction, which has to be heated to the target temperature of the process air.

- In gas combustion, one of the by-products is water. This water from combustion increases the humidity of the process air, which has a negative effect on the evaporation efficiency of the drying system.