- Products

-

Paper and board

- Water treatment

- Wood and chip yard

- Pulp making

- Pitch control

- Defoamers

- Press fabrics

- Detergents

- Strength enhancers (Biopolymer)

- Additives for wet strength broke pulping

- Additives for fiber modification

- Additives for peroxide bleaching

- Magnesium hydroxide

- Enzymes

- Organic Deposit Control

- Inorganic Deposit Control

- Edge showers

- Adjustable shower pipes

- Scanjet tank cleaners

- iFibre

- Starch Performer starch cooker

- Screw presses

- Double wire presses

- Disc filters

- Bale handling systems

- Baler wires

- Wire section

- Defoamers

- Dewatering elements, ceramics and PE

- iTable and dewatering elements optimization

- Dewatering elements

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Fabric cleaning and conditioning

- Slime control

- Banform SSB wires

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- TableVision – Activity Vision

- TableVision – Jet Vision

- TableVision -Line Vision

- TableVision – FlocVision

- Fabric Guides

- Retention agents

- Press section

- Drying

- Air flotation dryers and air turn solutions

- Fabric cleaning agents

- Degreasers

- Yankee roll release agents

- Bandry woven dryer fabrics

- Bandry PPS hydrolysis resistant dryer fabrics

- Bandry fabrics for broke conveyor

- Electric Infra-Red dryers – DryMaster™

- Electrical IR wet edge dryers – EdgeMaster™

- Gas IR and air drying systems – UniDryer®

- Energy recovery systems

- Gas IR dryers – GemDryer®

- Air dryers – FoilMaster™

- Coating

- Reeler and finishing

- Monitoring

-

Chemical pulping

- Water treatment

- Wood and chip yard

- Fiber line

- Drying

- Pitch control

- Defoamers

- Adjustable shower pipes

- Dewatering elements, ceramics and PE

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- Fabric Guides

- Safetymaster

- Strength enhancers (Biopolymer)

- Dewatering elements optimization

- Microbiological control

- Cylinder protection agent

- Forming fabrics

- Baler wires

- Recovery

- Condition monitoring

- Mechanical forest industry

- Biomaterials

- Green transition sectors

- Electrification and energy solutions

- Biogas and biofuels

- Petrochemicals

- Mining industry

- Metal industry

-

Paper and board

-

Partners

- Acrowood

- AstenJohnson Advanced Fabrics

- Bellmer

- BERGER

- Bollfilter

- Broadwire

- Buckau-Wolf GmbH

- CERNEY

- Eaton

- ECOWORLD

- FMW Industries

- GIG Karasek

- HeatHamster

- Herco

- Horst Sprenger

- IBS Austria GmbH

- Ichikawa

- Innocode

- Ircon Solaronics

- James Ross

- JTR ROLLS

- JUD AG

- Kapotek

- KOHO

- LMF

- MAAG Group

- Meidinger AG

- Papertech

- PGA

- Pieralisi

- Pirobloc

- PMS

- Renk Group

- Scanjet Systems

- Schaumann Bioenergy

- sera Group

- Spooner Industries Limited

- Teufelberger

- Transphase

- UMV Coating Systems

- Vakuo

- Sustainability

- Company

- Contact us

Products

Filters

Automatic Filters – Efficient and Maintenance-Free Filtration

Reliable Filters for Every Need

Looking for an efficient and reliable filtration solution that ensures continuous operation and reduces maintenance requirements? We offer a wide range of automatic filters designed for various flow rates, filtration grades, and liquid types. Our filters help enhance the efficiency of your processes while reducing downtime.

Benefits of Automatic Filters:

- Continuous Operation: Automatic filters run continuously without manual intervention. The backflush system ensures filter efficiency even during heavy fouling, minimizing downtime.

- Suitable for Hard-to-Reach Locations: Automatic filters enable filtration in areas where traditional maintenance would be challenging or impossible.

- Smart Monitoring: The central control system allows monitoring and management of all connected filters from one interface, improving reliability and optimizing system performance.

- Reduced Maintenance Needs: The automated backflush process minimizes the need for manual cleaning and filter replacement, reducing maintenance costs and downtime.

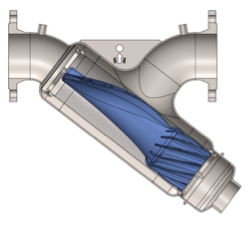

BOLLFILTER Filters – Efficient and Reliable Filtration

BOLLFILTER basket filters provide efficient filtration and durable performance for industrial applications.

Materials of Construction:

- Cast iron

- Steel

- Stainless steel

Filter Elements:

- Wash-resistant steel and stainless steel elements

- Disposable paper, polyester, and fiberglass cartridges

Applications:

- Water filtration

- Fuel and lubrication oil filtration

- Chemical filtration

New SOLOBOLL Automatic Filter

- Compact size and low investment

- Easy to integrate into factory systems

- Trial run available

- Three sizes: DN50, DN80, DN100

- Filtration range: Coarse filtration 100μm – 500μm

- Stainless steel housing

- In-line design

- 24VDC power supply

- SOLOBOLL offers a compact and cost-effective filtration solution!

Duplex Filters – Continuous Operation and Safety

BOLLFILTER Duplex filters ensure continuous operation and high safety in demanding industrial processes.

- Continuous Filtration: The duplex design allows filter element change without interrupting the process.

- Versatile Filter Elements: Customized solutions for fine and coarse filtration, as well as specialty materials.

- Double Block and Bleed Technology: Improves safety by simultaneously closing both inlet and outlet during maintenance, reducing leakage and contamination risks.

Simplex Filters – Simple and Efficient Solution

BOLLFILTER Simplex filters offer a reliable and optimized filtration solution when the system can be shut down for maintenance.

Benefits:

- Compact and efficient design – Easy to integrate into various systems and installation spaces.

- Easy maintenance – Filter elements can be removed, cleaned, and reinstalled effortlessly.

- Reliable filtration performance – Removes impurities and protects equipment from wear and clogging.