- Products

-

Paper and board

- Water treatment

- Wood and chip yard

- Pulp making

- Pitch control

- Defoamers

- Press fabrics

- Detergents

- Strength enhancers (Biopolymer)

- Additives for wet strength broke pulping

- Additives for fiber modification

- Additives for peroxide bleaching

- Magnesium hydroxide

- Enzymes

- Organic Deposit Control

- Inorganic Deposit Control

- Edge showers

- Adjustable shower pipes

- Scanjet tank cleaners

- iFibre

- Starch Performer starch cooker

- Screw presses

- Double wire presses

- Disc filters

- Bale handling systems

- Baler wires

- Wire section

- Defoamers

- Dewatering elements, ceramics and PE

- iTable and dewatering elements optimization

- Dewatering elements

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Fabric cleaning and conditioning

- Slime control

- Banform SSB wires

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- TableVision – Activity Vision

- TableVision – Jet Vision

- TableVision -Line Vision

- TableVision – FlocVision

- Fabric Guides

- Retention agents

- Press section

- Drying

- Air flotation dryers and air turn solutions

- Fabric cleaning agents

- Degreasers

- Yankee roll release agents

- Bandry woven dryer fabrics

- Bandry PPS hydrolysis resistant dryer fabrics

- Bandry fabrics for broke conveyor

- Electric Infra-Red dryers – DryMaster™

- Electrical IR wet edge dryers – EdgeMaster™

- Gas IR and air drying systems – UniDryer®

- Energy recovery systems

- Gas IR dryers – GemDryer®

- Air dryers – FoilMaster™

- Coating

- Reeler and finishing

- Monitoring

-

Chemical pulping

- Water treatment

- Wood and chip yard

- Fiber line

- Drying

- Pitch control

- Defoamers

- Adjustable shower pipes

- Dewatering elements, ceramics and PE

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- Fabric Guides

- Safetymaster

- Strength enhancers (Biopolymer)

- Dewatering elements optimization

- Microbiological control

- Cylinder protection agent

- Forming fabrics

- Baler wires

- Recovery

- Condition monitoring

- Mechanical forest industry

- Biomaterials

- Green transition sectors

- Electrification and energy solutions

- Biogas and biofuels

- Petrochemicals

- Mining industry

- Metal industry

-

Paper and board

-

Partners

- Acrowood

- AstenJohnson Advanced Fabrics

- Bellmer

- BERGER

- Bollfilter

- Broadwire

- Buckau-Wolf GmbH

- CERNEY

- Eaton

- ECOWORLD

- FMW Industries

- GIG Karasek

- HeatHamster

- Herco

- Horst Sprenger

- IBS Austria GmbH

- Ichikawa

- Innocode

- Ircon Solaronics

- James Ross

- JTR ROLLS

- JUD AG

- Kapotek

- KOHO

- LMF

- MAAG Group

- Meidinger AG

- Papertech

- PGA

- Pieralisi

- Pirobloc

- PMS

- Renk Group

- Scanjet Systems

- Schaumann Bioenergy

- sera Group

- Spooner Industries Limited

- Teufelberger

- Transphase

- UMV Coating Systems

- Vakuo

- Sustainability

- Company

- Contact us

Products

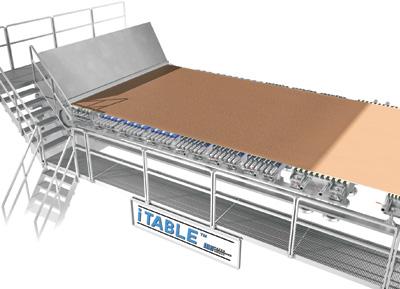

iTable and dewatering elements optimization

The iTABLE® is the first fully adjustable sheet forming zone for Fourdrinier machines. It enables precise control of dewatering and fibre suspension activity. Starting from the headbox all the way to the end of the forming zone, where fibre mobility ends. The iTABLE® increases dewatering capacity, improves paper properties & minimizes raw material, energy and chemical consumption.

- Increased production through increased dewatering capacity and machine speed.

- Reduced basis weight with identical or improved paper properties.

- Improved formation, strength and surface properties.

- Reduced costs for raw materials and chemicals with the same paper properties.

- Reduced energy demand (electricity, steam).

- Reproducibility, giving you increased homogeneity across the entire portfolio.

Audit for wet end optimization and rebuilds

- Maximize the performance of your wet end.

- As part of this audit, our experts perform a comprehensive inspection of your machine’s wire section. Formation, paper properties, dewatering capacities and much more are precisely analyzed and measures for optimization are proposed. Often the optimum settings are lost, e.g. due to speed changes, the use of alternative raw materials or the wear of dewatering elements. In many cases, production targets also change over time. Therefore, we recommend to have the entire wire section audited and optimized on a regular basis – this is the only way to get the best out of your machine.

- Comprehensive inspection of your machine‘s wire section.

- Assessment of current limitations and issues.

- Project proposal featuring solutions for achieving production targets, such as production increase, quality improvement, and energy savings.

Contact us

Mika Puhakainen

- Sales Manager, Process Equipment

- mika.puhakainen@banmark.fi

- +358 400 498812

Available

- FI

- NO

- SE