- Products

-

Paper and board

- Water treatment

- Wood and chip yard

- Pulp making

- Pitch control

- Defoamers

- Press fabrics

- Detergents

- Strength enhancers (Biopolymer)

- Additives for wet strength broke pulping

- Additives for fiber modification

- Additives for peroxide bleaching

- Magnesium hydroxide

- Enzymes

- Organic Deposit Control

- Inorganic Deposit Control

- Edge showers

- Adjustable shower pipes

- Scanjet tank cleaners

- iFibre

- Starch Performer starch cooker

- Screw presses

- Double wire presses

- Disc filters

- Bale handling systems

- Baler wires

- Wire section

- Defoamers

- Dewatering elements, ceramics and PE

- iTable and dewatering elements optimization

- Dewatering elements

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Fabric cleaning and conditioning

- Slime control

- Banform SSB wires

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- TableVision – Activity Vision

- TableVision – Jet Vision

- TableVision -Line Vision

- TableVision – FlocVision

- Fabric Guides

- Retention agents

- Press section

- Drying

- Air flotation dryers and air turn solutions

- Fabric cleaning agents

- Degreasers

- Yankee roll release agents

- Bandry woven dryer fabrics

- Bandry PPS hydrolysis resistant dryer fabrics

- Bandry fabrics for broke conveyor

- Electric Infra-Red dryers – DryMaster™

- Electrical IR wet edge dryers – EdgeMaster™

- Gas IR and air drying systems – UniDryer®

- Energy recovery systems

- Gas IR dryers – GemDryer®

- Air dryers – FoilMaster™

- Coating

- Reeler and finishing

- Monitoring

-

Chemical pulping

- Water treatment

- Wood and chip yard

- Fiber line

- Drying

- Pitch control

- Defoamers

- Adjustable shower pipes

- Dewatering elements, ceramics and PE

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- Fabric Guides

- Safetymaster

- Strength enhancers (Biopolymer)

- Dewatering elements optimization

- Microbiological control

- Cylinder protection agent

- Forming fabrics

- Baler wires

- Recovery

- Condition monitoring

- Mechanical forest industry

- Biomaterials

- Green transition sectors

- Electrification and energy solutions

- Biogas and biofuels

- Petrochemicals

- Mining industry

- Metal industry

-

Paper and board

-

Partners

- Acrowood

- AstenJohnson Advanced Fabrics

- Bellmer

- BERGER

- Bollfilter

- Broadwire

- Buckau-Wolf GmbH

- CERNEY

- Eaton

- ECOWORLD

- FMW Industries

- GIG Karasek

- HeatHamster

- Herco

- Horst Sprenger

- IBS Austria GmbH

- Ichikawa

- Innocode

- Ircon Solaronics

- James Ross

- JTR ROLLS

- JUD AG

- Kapotek

- KOHO

- LMF

- MAAG Group

- Meidinger AG

- Papertech

- PGA

- Pieralisi

- Pirobloc

- PMS

- Renk Group

- Scanjet Systems

- Schaumann Bioenergy

- sera Group

- Spooner Industries Limited

- Teufelberger

- Transphase

- UMV Coating Systems

- Vakuo

- Sustainability

- Company

- Contact us

Products

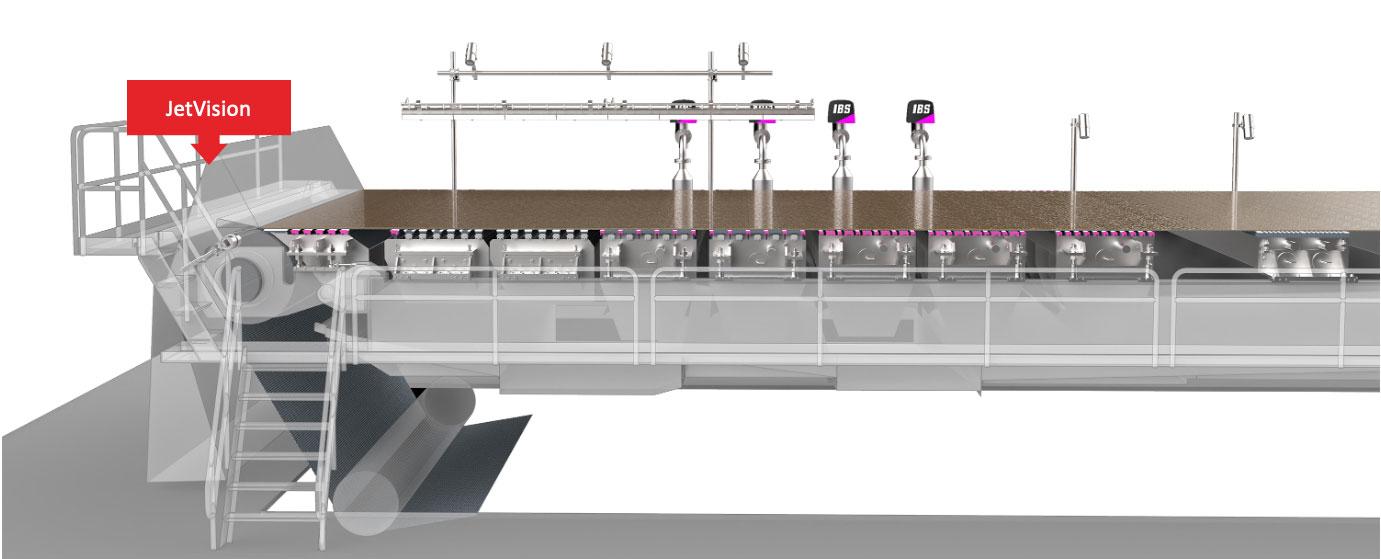

TableVision – Jet Vision

- Jet cut-through monitoring.

- Traditionally, papermakers visually observe the jet cut-through by physically approaching the machine and adjusting the headbox or manually moving the forming board to achieve the desired cut-through. This approach is heavily dependent on user skill level and attentiveness, and adjustments must be followed locally at the forming board. JetVision continuously monitors the jet cut-through by mounting a camera on the machine frame and provides the live cut-through image as well as a trend via the software user interface.

- Continuously monitor live jet cut-through remotely from the operator station.

- IBS algorithm shows actual jet cut-through length and trend.

- Live and historical trend information to verify operating conditions that achieve the best quality.

- Control loop for automatic cut-through control with motorized IBS flexLINE forming board possible.

- Improve and stabilize your strength parameters.