- Products

-

Paper and board

- Water treatment

- Wood and chip yard

- Pulp making

- Pitch control

- Defoamers

- Press fabrics

- Detergents

- Strength enhancers (Biopolymer)

- Additives for wet strength broke pulping

- Additives for fiber modification

- Additives for peroxide bleaching

- Magnesium hydroxide

- Enzymes

- Organic Deposit Control

- Inorganic Deposit Control

- Edge showers

- Adjustable shower pipes

- Scanjet tank cleaners

- iFibre

- Starch Performer starch cooker

- Screw presses

- Double wire presses

- Disc filters

- Bale handling systems

- Baler wires

- Wire section

- Defoamers

- Dewatering elements, ceramics and PE

- iTable and dewatering elements optimization

- Dewatering elements

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Fabric cleaning and conditioning

- Slime control

- Banform SSB wires

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- TableVision – Activity Vision

- TableVision – Jet Vision

- TableVision -Line Vision

- TableVision – FlocVision

- Fabric Guides

- Retention agents

- Press section

- Drying

- Air flotation dryers and air turn solutions

- Fabric cleaning agents

- Degreasers

- Yankee roll release agents

- Bandry woven dryer fabrics

- Bandry PPS hydrolysis resistant dryer fabrics

- Bandry fabrics for broke conveyor

- Electric Infra-Red dryers – DryMaster™

- Electrical IR wet edge dryers – EdgeMaster™

- Gas IR and air drying systems – UniDryer®

- Energy recovery systems

- Gas IR dryers – GemDryer®

- Air dryers – FoilMaster™

- Coating

- Reeler and finishing

- Monitoring

-

Chemical pulping

- Water treatment

- Wood and chip yard

- Fiber line

- Drying

- Pitch control

- Defoamers

- Adjustable shower pipes

- Dewatering elements, ceramics and PE

- Fabric tensioning

- Doctors, oscillating and shower systems

- SuperSteamVac steam box

- Edge trimming and tail cutter, ruby nozzles

- Edge showers and edge trimming

- Vacuum control valves

- Online monitoring and controlling – Online-PDC

- Online monitoring and controlling – Flowmaster

- Fabric Guides

- Safetymaster

- Strength enhancers (Biopolymer)

- Dewatering elements optimization

- Microbiological control

- Cylinder protection agent

- Forming fabrics

- Baler wires

- Recovery

- Condition monitoring

- Mechanical forest industry

- Biomaterials

- Green transition sectors

- Electrification and energy solutions

- Biogas and biofuels

- Petrochemicals

- Mining industry

- Metal industry

-

Paper and board

-

Partners

- Acrowood

- AstenJohnson Advanced Fabrics

- Bellmer

- BERGER

- Bollfilter

- Broadwire

- Buckau-Wolf GmbH

- CERNEY

- Eaton

- ECOWORLD

- FMW Industries

- GIG Karasek

- HeatHamster

- Herco

- Horst Sprenger

- IBS Austria GmbH

- Ichikawa

- Innocode

- Ircon Solaronics

- James Ross

- JTR ROLLS

- JUD AG

- Kapotek

- KOHO

- LMF

- MAAG Group

- Meidinger AG

- Papertech

- PGA

- Pieralisi

- Pirobloc

- PMS

- Renk Group

- Scanjet Systems

- Schaumann Bioenergy

- sera Group

- Spooner Industries Limited

- Teufelberger

- Transphase

- UMV Coating Systems

- Vakuo

- Sustainability

- Company

- Contact us

Products

Ultra filters

Ultra Filtration Filters – Precision Filtration at the Molecular Level

Our ultra filtration systems provide advanced filtration by separating particles and solutes at the molecular level. These filters allow water, dissolved ions, and small molecules to pass through while effectively capturing larger molecules, colloids, and suspended solids.

Key Features:

- High-precision filtration – Removes contaminants while retaining essential dissolved ions

- Semipermeable membranes – Pore sizes between 1 and 100 nanometers for optimal filtration

- Efficient & reliable – Ensures high-quality filtration with minimal maintenance

We specialize in customized fine filtration systems designed to meet your specific needs.

Fine filter unit

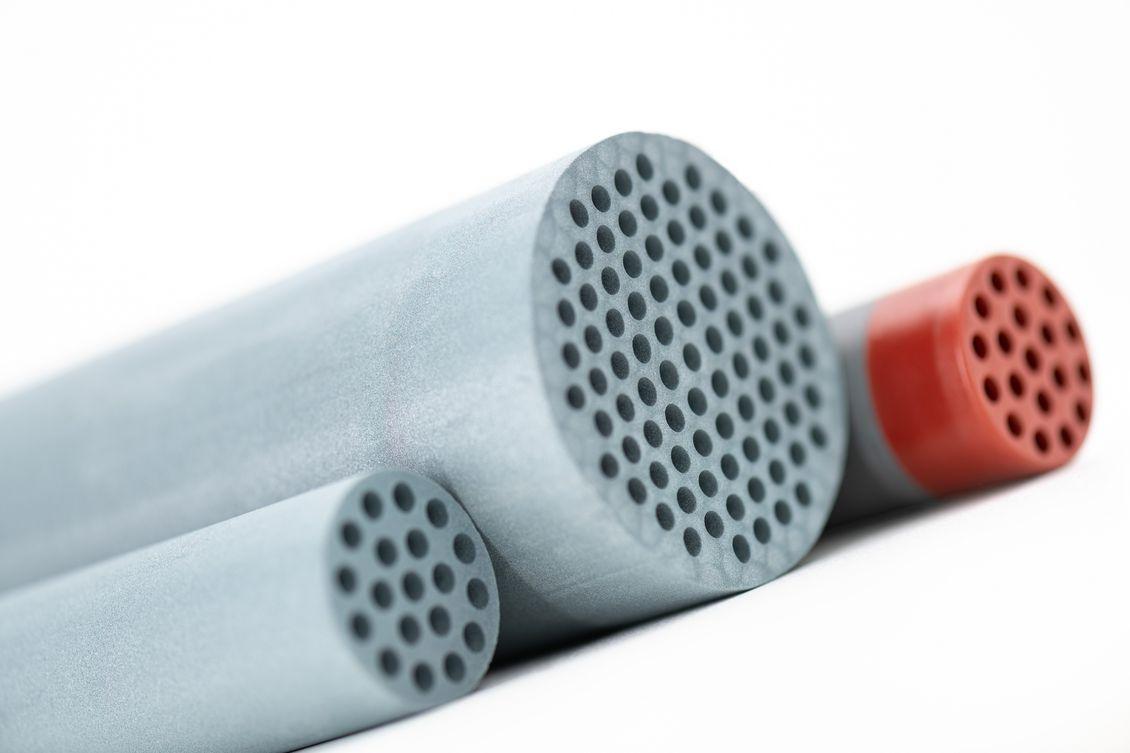

Ceramic Filter Elements – High-Performance Filtration

Our ceramic filter elements provide durable and efficient filtration for various industrial applications. Designed for high performance, they ensure excellent filtration efficiency and longevity.

Technical Specifications:

- Filter Element: High-quality ceramic filter elements

- Pressure Stage: PN 6

- Operating Temperature: Up to 60ºC

- Filter Housing: Stainless steel 1.4571 or higher

- Optional Features: Fully automated monitoring and control for seamless operation

- Membrane Design: Engineered according to tested and proven processe

Your Expert Partner in Filtration Technology

With years of expertise in filtration technology, we are your go-to partner for customized membrane system solutions. Our commitment extends beyond just providing high-quality filtration – we build long-term partnerships, offering:

- Global customer support

- Innovative filtration solutions

- Best-in-class processes

- Strong industry partnerships

- Added value for your operations

BOLL FineFilterUnits – Advanced Water Treatment

Our BOLL FineFilterUnits are complete water treatment systems powered by the latest membrane technology, ensuring superior filtration performance and reliability.

SiC Ceramic Membrane Technology – Extreme Durability & Performance

Silicon carbide (SiC) is one of the hardest materials in the world, making it ideal for high-performance filtration. Our SiC ceramic membrane technology offers:

- Unmatched durability – High mechanical resistance

- Exceptional filtration efficiency – Highest flux and permeability

- Superior hydrophilicity – Water-loving properties for optimized filtration

- Corrosion resistance – Ideal for demanding applications

Our ceramic membrane consists of three layers:

Ceramic Tubular Membrane – Multi-Layered Filtration Technology

Our ceramic tubular membranes are designed with a three-layer structure, ensuring high mechanical strength, optimal support, and superior filtration efficiency.

Membrane Structure:

- Substrate – Provides mechanical strength and durability

- Intermediate Layer – Acts as a support layer for enhanced stability

- Membrane – Ensures high selectivity and filtration efficiency

- This advanced design allows for high-performance filtration, extended lifespan, and resistance to extreme operating conditions.

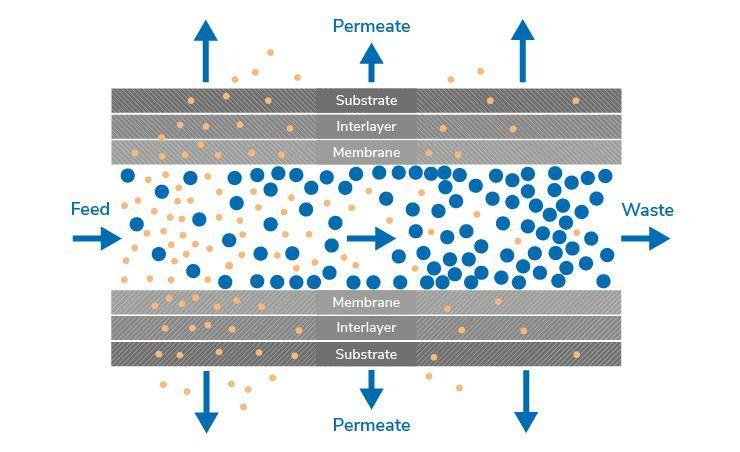

Ceramic Tubular Membrane – High-Performance Filtration

Our ceramic tubular membrane modules are designed for efficient filtration of liquids with high levels of dissolved or suspended solids, making them ideal for applications such as oily wastewater treatment.

How It Works:

- Dual-Tube Design – The inner tube functions as the membrane, while the outer tube acts as the protective shell.

- Durable Construction – The ceramic membrane tubes are housed in a long PVC casing for enhanced protection and longevity.

- Tangential Cross-Flow Filtration – The inlet flow moves along the membrane tube, allowing filtered liquid to pass into the outer shell, ensuring efficient separation of contaminants.

Key Benefits:

- High durability & chemical resistance

- Effective filtration for challenging wastewater streams

- Optimized for industrial applications

Flow Filtration with Ceramic Pipe Membranes

Our ceramic pipe membranes utilize high-pressure filtration to effectively separate water from suspended solids, ensuring efficient and reliable performance.

How It Works:

- Pressurized Filtration – Water is forced into the membrane pipes under pressure.

- Separation Process –

- Permeate (filtered water) passes through the porous ceramic membrane into the outer pipe.

- Retentate (solid or suspended particles) remains in the inner pipe and is discharged into a reservoir.

- Continuous Operation – The filtration process can be restarted, ensuring continuous and efficient filtration.

Key Benefits:

- Highly efficient separation of solids and liquids

- Durable and chemical-resistant ceramic membranes

- Optimized for industrial & wastewater applications

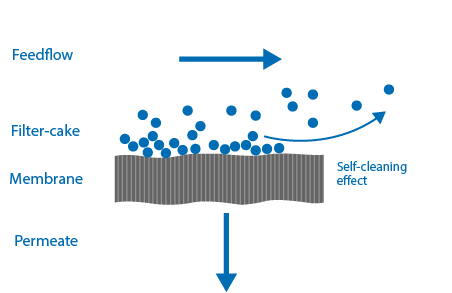

Tubular Membrane Filtration – Efficient & Space-Saving

Filtration with tubular membranes offers a highly efficient and compact alternative to traditional clarification filtration systems.

Why Choose Tubular Membranes?

- Superior Filtration Efficiency – Effectively separates solids and liquids for cleaner output.

- Space-Saving Design – Requires less space compared to conventional clarification systems.

- Continuous & Reliable Operation – Ensures consistent performance with minimal downtime.

- Durable & Long-Lasting – Designed for high resistance to chemicals and extreme conditions.